In order to develop innovative products for the medical industry it is necessary to test a concept before transitioning to product development and mass production.

Zriha Medical advises the customer about the overall feasibility study of the product, production options and viability. The product feasibility stage includes building a computer model, allowing the product performance to be refined and improved by engineering simulations.

Once the feasibility phase is complete, the company's engineers support the customer in the transition from the development phase to mass production, providing extensive engineering assistance.

One of the significant stages in product development is the prototype production stage. Production of prototypes allows the opportunity to illustrate an idea, and to test the usefulness of the product in an economic and practical examination. The prototype manufacturing department at Zriha Medical recognizes the importance of producing high-quality and accurate prototypes that approach the final product with the highest level of finish, in order to enable its customers to test the product as a whole.

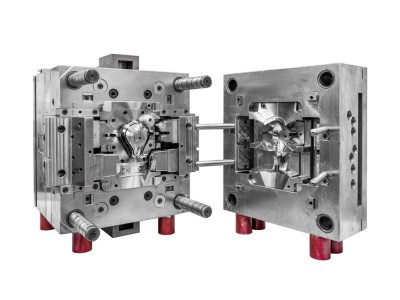

In fact, prototype production is a preliminary step in producing a mold designed for serial production. The choice to produce prototypes, saves the customer the need to make a high financial investment in the production of the mold, and allows them to make changes when needed.